| Monday | 7:30AM - 8:00PM |

| Tuesday | 7:30AM - 8:00PM |

| Wednesday | 7:30AM - 8:00PM |

| Thursday | 7:30AM - 8:00PM |

| Friday | 7:30AM - 8:00PM |

| Saturday | 8:00AM - 8:00PM |

| Sunday | 9:00AM - 8:00PM |

| Monday | 7:00AM - 6:00PM |

| Tuesday | 7:00AM - 6:00PM |

| Wednesday | 7:00AM - 6:00PM |

| Thursday | 7:00AM - 6:00PM |

| Friday | 7:00AM - 6:00PM |

| Saturday | 8:30AM - 5:30PM |

| Sunday | Closed |

Deutz Fahr

Deutz-Fahr 7 Series Stage 4 (Tier4 Final)

-

ID # 27950633

- Back ID:27950633

- Book a Demo

- Get Directions

TOP GERMAN TECHNOLOGY

TOP GERMAN TECHNOLOGYSuccess is achieved by enterprises that are able to tackle every task throughout the season using the lowest possible amount of resources and being effective with the time available. Equally, every penny counts when it comes to reducing production costs. DEUTZ-FAHR has developed the new 7 Series for such businesses. The two new 7 Series models deliver up to 246 HP and stand out for a range of trademark German characteristics: high quality, high precision and reliability combined with cutting-edge technology in terms of both cost-effectiveness and comfort. The 7 Series represents the culmination of highly innovative and intelligent tractor technology manufactured at our new facility in Lauingen, Germany, offering the exceptional comfort of the MaxiVision 2 cab, intuitive controls, a newly designed armrest, state-of-the-art precision farming systems, highly efficient engine and transmission technology, innovative axles and brakes which ensure optimal driving comfort and maximum safety. Furthermore, the hydraulic systems and lift capacity both front and rear, compliment the overall 7 Series specification making this tractor the ideal partner for increasing the productivity of professional contractors and agricultural businesses – both in the field and on the road. |

|

Deutz Common Rail. High pressure common rail injection system, with two lubricated injection pumps integrated in the engine block, and an innovative combustion chamber configuration for superlative power and torque over a wide range of engine speeds. |

|

Selective Catalytic Reduction. The tractor is equipped with a Selective Catalytic Reduction (SCR) exhaust cleaning system that utilises a 32.5% urea-water solution—AdBlue—for treating exhaust fumes. An additional AdBlue tank is fitted on one side of the tractor. |

|

Designed with specific technical solutions and constructed with special materials, the injection system is fully compatible with fuels containing up to 100% biodiesel. |

|

ENERGY SAVING A system integrated in the hydraulic system which reduces thermal losses, improves efficiency and recovers energy that would otherwise be wasted. When the lift and distributors are not in use, a solenoid valve returns the hydraulic fluid flow to the transmission housing. POWER BRAKES A system ensuring an effective and immediate response from the brake system in all conditions with minimal pressure on the pedal by maintaining a constant pressure in the relative hydraulic circuit. |

|

An electronic system which automatically engages and disengages drive to the front wheels and the differential lock in relation to steering angle and speed. |

|

Optimised power curve usage, reduced consumption and improved driver comfort by maintaining lower engine speeds and using the engine at speeds close to maximum torque. |

|

A system maximising the potential of the Sense Clutch shuttle for superlative manoeuvrability. Ideal for jobs involving frequent stops and starts. |

|

Hydraulic reverse shuttle with two multiplate wet clutches and an electronic control unit. |

|

COMMANDER CONTROL Joystick-controlled control functions. The operator can easily and conveniently control selected tractor functions. SENSORS This advanced technology tractor is equipped with several sensors monitoring the correct operation of all machine systems and functions. Sensor signals are collected and analysed by a control panel which adjusts tractor settings on the basis of this information in order to meet current needs. ELECTRONIC ENGINE GOVERNOR The system monitors a set of engine parameters, and optimises engine function by adjusting injection accordingly. Automated for total simplicity: lets the driver set, store and recall the most appropriate engine speed for the job in hand. |

|

The unique features offered by MaxiVision 2 cab can be seen inside and also from outside. When it comes to ease of use and ergonomics, the new 7 Series takes care of work for the driver to the extent permitted by current technology. The new InfoCentrePro on the dashboard features a 5" colour display, providing the driver with a stream of data about the tractor’s operating conditions. It offers maximum convenience in terms of settings and information. In order to allow precise, stress-free work in all lighting conditions, the tractor can be fitted with an optional 40.000 lumen LED package with four working headlights. The interior is designed for the driver's comfort - reduced engine noise, vibrations and heat due to the cab and engine hood being separated. The new hood encapsulates the latest, highly contemporary look of the DEUTZ-FAHR tractor family, while its compact design also ensures outstanding forward visibility. The best possible view of rear attachments is guaranteed by the rearward position of the cab. |

|

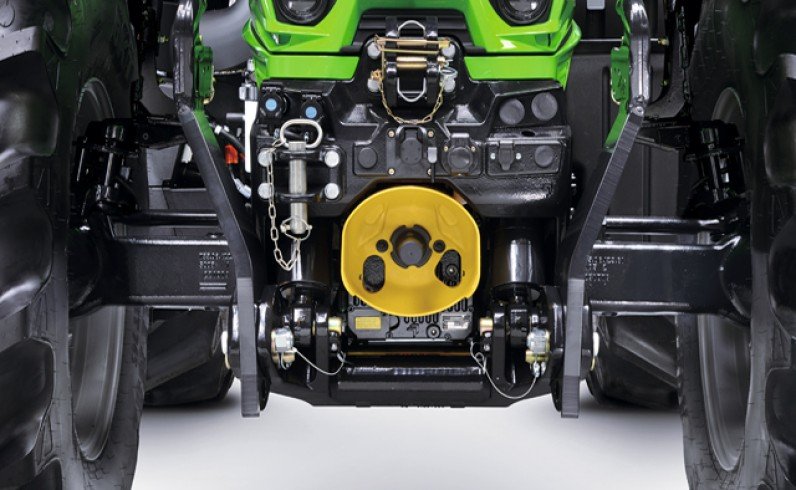

The productivity of a tractor depends directly on the equipment it can drive. The aim is to reduce the amount of distance travelled through increasingly large and heavy attachment combinations. This is where the 7 Series clearly demonstrates its strength. With three PTO speeds (540ECO/1000/1000ECO) at the rear and 1000 or 1000ECO at the front, all work can be carried out very efficiently. Thanks to the reduced engine speed characteristics, coupled with the ECO power take-off sysytems, fuel consumption is significantly reduced. All hydraulic and PTO functions can be easily set and controlled from the armrest in the cab. An external control of hydraulics, rear lift and PTO from both sides of the tractor is also possible. |

|

Productivity needs maximum vehicle control - both in the field and on the road. At top speed as well as on challenging ground conditions and with the heaviest equipment. The 7 Series gives you a uniquely valuable sensation: safety in every situation. The new heavy duty front axle with suspension and the braking system of the 7 Series are unique in this tractor class. The intelligent and adaptive suspension system give the new 7 Series maximum stability – both during heavy tillage operations and when driving loads. The innovative suspension concept stabilises the tractor during all transport operations and boosts driving safety. In order to ensure better handling on uneven ground, the dampers are mounted on the front side of the axle. The 7 Series is the only standard tractor that is fitted with high performance dry disc brakes on the front axle. The additional Booster brake system ensures maximum braking performance with the lightest pedal pressure. No other standard tractor offers a heavy duty front axle, dry disc brakes combined with the booster brake system and improved safety. |

|

The new 7 Series is equipped with a completely redesigned engine in terms of environmental impact and cost-effectiveness. The new Deutz 6.1 Stage 4 (Tier4 Final) engine is more responsive, offers higher reserve torque and has a higher torque at lower rpms. At the same time, consumption of fuel and AdBlue has been reduced by 5 %, compared to the previous generation. The revised exhaust system features SCR after treatment and an additional, passive DPF (diesel particulate filter). DPF offers three advantages compared to the usual active filters: no fuel injection enters the filter, less heat is generated around the unit and the filter regenerates much more quickly. This saves fuel and money while conforming to all international emission standards. The efficiency of the engine is supported by Electronic Visco fan and the redesigned, compact and high-performance cooling system. The patented cooling system can be opened completely, which makes servicing much more straightforward. A pre-cleaning system on the air intake slots prevents dirt from entering the air filter, making a substantial difference to service costs. The Deutz 6.1 Stage 4 (Tier4 Final) engine – modern technology made in Germany – is synonymous with the highest levels of know-how and efficiency, allowing you to achieve maximum productivity. |

|

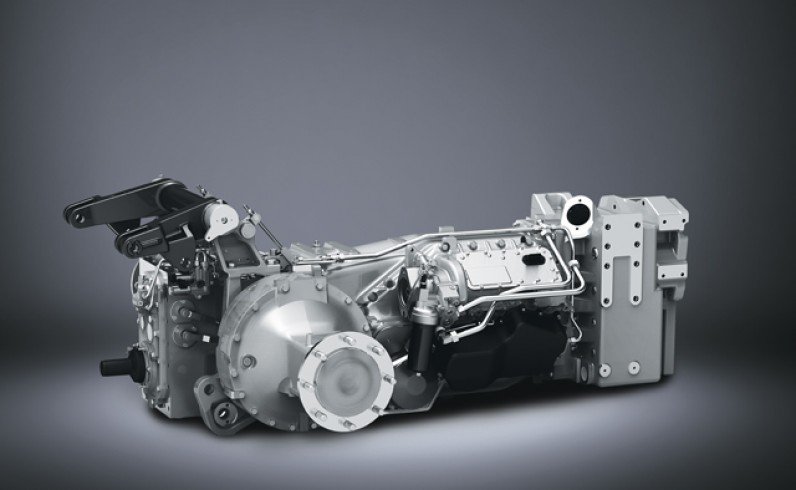

The new 7 Series is fitted with state-of-the-art electronically controlled continuously variable TTV transmission technology. It is a solid concept that has been tried and tested over the years, now with new software for even better performance. DEUTZ-FAHR is the only manufacturer that offers a 60 Km/h tractor in such a compact design. All final speeds of 40 Km/h, 50 Km/h or 60 Km/h can be reached at a reduced engine speed, which is extremely fuel efficient. Overall, the speed range extends from 0.2 Km/h to 60 Km/h. For field work, the TTV transmission system operates most efficiently at all speeds. The highly comfortable TTV transmission is extremely efficient thanks to its four mechanical stages, which change automatically. Engine and transmission management are fully integrated, providing a comfortable automatic system for mechanical range shifting. Up to four cruise speeds can be stored in order to optimise work processes. A new trailer stretch mode increases driving safety on hilly terrain. Every single detail of the TTV transmission system has been designed to maximise the productivity of the 7 Series |

|

The new 7 Series provides attachment area technology that was previously available only in higher power classes. The rear attachment area features up to five hydraulic control valves, while the front attachment area has two. The absolute highlight is that all valves are proportionally controlled. The new hydraulic system of the 7 Series allows a position-controlled front linkage to be equipped. Until now, such advanced technology was only available on the 9 Series. The lifting capacity is up to 5480 kg, an impressive figure. Additionally, equipment is positioned much closer to the tractor with the newly integrated front linkage concept, which substantially enhances lifting capacity. The front mounting area also features an integrated ISOBUS socket. The hydraulic pump delivers an output of 120 L/min as standard or 160 L/min on request. The load sensing system is included as standard. A separate pump supplies the steering so that the working hydraulic system is not compromised. The rear lifting capacity is 10000 kg. |