| Monday | 7:30AM - 8:00PM |

| Tuesday | 7:30AM - 8:00PM |

| Wednesday | 7:30AM - 8:00PM |

| Thursday | 7:30AM - 8:00PM |

| Friday | 7:30AM - 8:00PM |

| Saturday | 8:00AM - 8:00PM |

| Sunday | 9:00AM - 8:00PM |

| Monday | 7:00AM - 6:00PM |

| Tuesday | 7:00AM - 6:00PM |

| Wednesday | 7:00AM - 6:00PM |

| Thursday | 7:00AM - 6:00PM |

| Friday | 7:00AM - 6:00PM |

| Saturday | 8:30AM - 5:30PM |

| Sunday | Closed |

Macdon

MacDon D1 Draper Headers & FD1 FlexDraper® Headers for Combines

-

ID # 27950739

- Back ID:27950739

- Book a Demo

- Get Directions

|

The next level of incredible draper performance

Most combine headers perform well in perfect harvesting conditions, but when was the last time you had perfect conditions? MacDon FlexDraper® and Draper Headers are designed to maximize productivity in the most challenging harvesting situations, from our Active Float System that keeps our headers true-to-the-ground, to the outstanding performance of our reel. Available in sizes up to 13.7 m (45'), MacDon combine drapers are built tough to deliver worry-free harvesting performance with any crop, in any condition, and on any combine. |

Active Float System The MacDon D65 combine header features a Dual Span (split) Reel. This design allows the reel to operate very closely to the cutting components in short or down and tangled crops even over rough, uneven ground without clipping the fingertips. |

Combine Interchangeability Combine Interchangeability

Thanks to the FM100, MacDon Draper Headers are designed to fit all major brand combines with an easy-to-install completion package. This multi-brand compatibility and interchangeability mean your investment will hold its value until it's time to update your header. |

|

The feed auger of the FM100 has been engineered to maximize crop feeding. Long (154 mm (6")) tine extension, aggressively engage high volumes of crop. The in-feed crop width can be tailored to match specific combine feeder houses. |

|

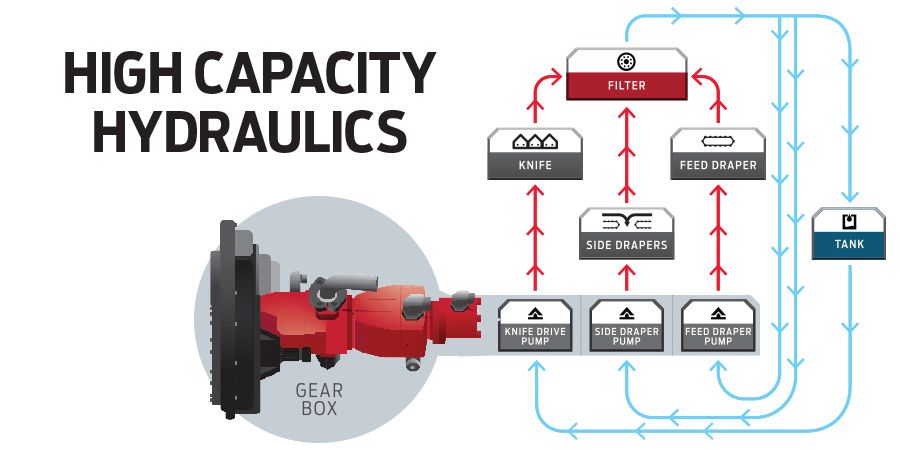

MacDon's new hydraulic system features individual fully filtered circuits for the knife drive, side drapers, and feed draper. These individual circuits provide increased side draper speed, along with greater capacity and reliability. The 1 Series hydraulics make it possible for an optional in-cab side draper speed control, allowing on-the-go adjustment. |

Amazing Reel Performance Amazing Reel Performance

Unlike other headers, the movement of our heavy-duty reel picks up and gently places crop onto the drapers. The reel features a uniquely shaped cam, which allows the fingers to get underneath lodged crop and pick it up before it's cut. Along with the header tilt control, which hydraulically angles the knife from the cab, and fore-aft reel positioning, our headers can reduce, or altogether eliminate, the need for crop lifters. |

|

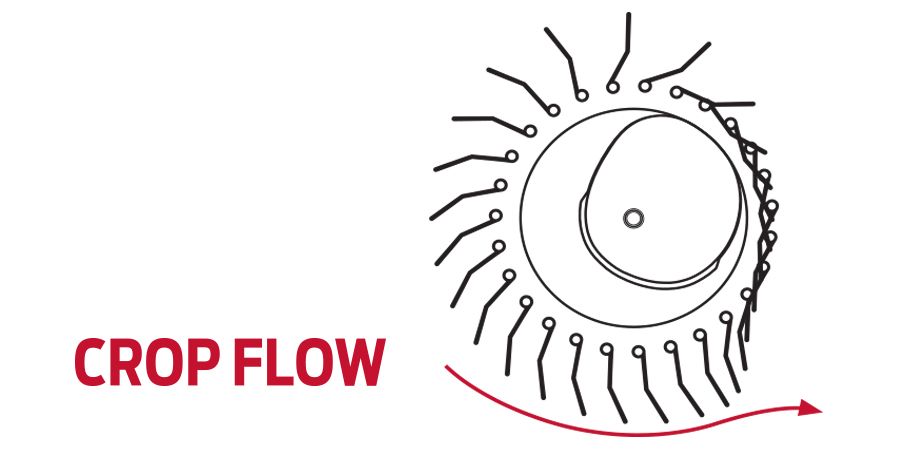

Active Crop Flow MacDon's Active Crop Flow gently places crop on the side drapers heads-first and swiftly moves it onto the feed draper, where it's scooped up into the combine's feeder house. Heads-first feeding promotes peak combine efficiency by saving fuel, improving threshing action, creating a better straw distribution, and allowing for a more productive harvest overall. Because this harvesting method is more efficient in damp and moist conditions, you can start earlier and work later into the evening. |

On-The-Go Control

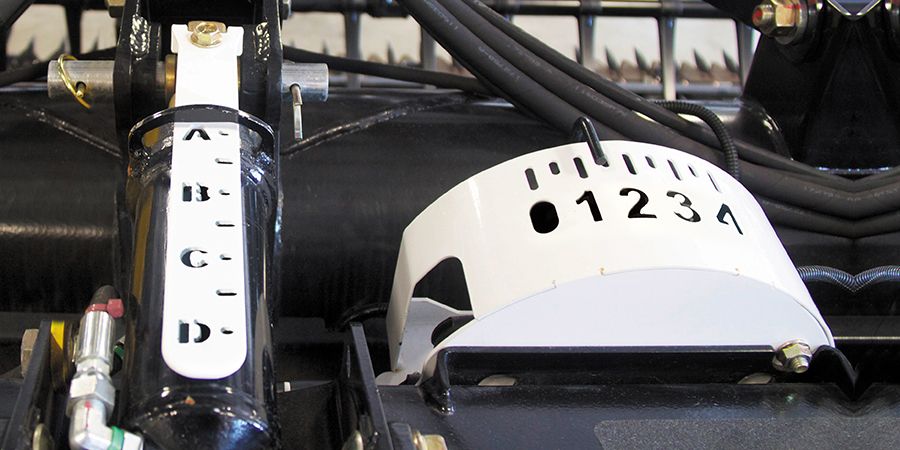

Automatic Header Height controls allow the operator to choose ground pressure, cutting height, and header tilt, all right from the operator's seat. When used with the optional Stabilizer Wheels, it allows for automatic cut heights of 30-560 mm (1-22").

|

Multi-Crop Harvesting Solution MacDon’s D1 and FD1 Series headers are true multi-crop harvesting machines able to take down cereals, oilseeds, beans, and just about any crop in any condition. The FD1 FlexDraper® switches easily from flex to a solid frame with the quick flip of a lever, giving you the ultimate flexibility to move from one crop type to another. Any crop, any condition, MacDon Drapers are the ultimate performance upgrade for your combine. |

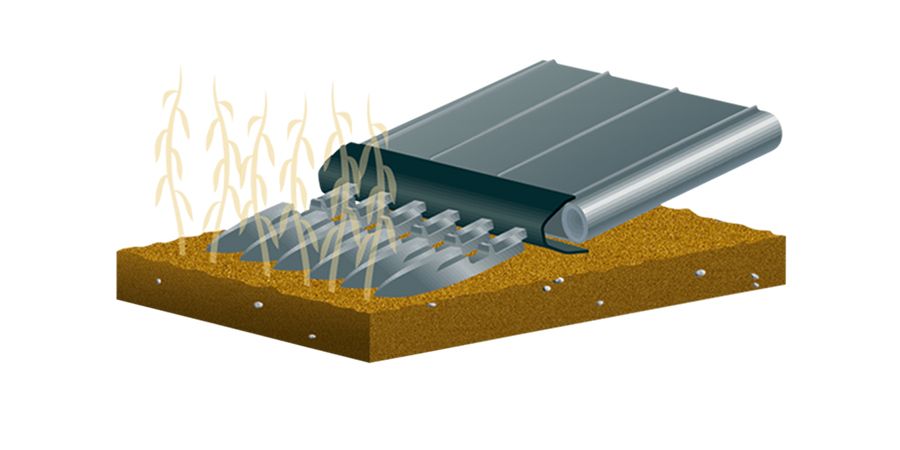

A Consistently Close Shave MacDon’s patented C-shaped, low-profile cutterbar design allows ground level cutting for the most consistently close shave of your fields. Featuring a heavy-duty knife drive and in-cab knife angle control, this cutting system allows you to match any harvest conditions. The ultra-smooth ground-facing surface of our cutterbar helps our headers glide along the ground for a smooth close cut every time. |

Aggressive Upper Cross Auger Aggressive Upper Cross Auger

The optional Upper Cross Auger helps to move heavy, bushy, high-volume crops, like canola and peas, to the center of the header for smooth feeding. Featuring twin pitch flighting at the center of the auger to aggressively drive crop down and into the feed auger of MacDon's FeedMaX system. Available for all header sizes, the upper cross auger is attached in front of the back tube and features a shut-off valve to disengage the drive when not required. |

|

Self-Contained Transport Our Slow Speed Transport package allows you to tow your D1 and FD1 Series Headers up to 20 mph (32 km/h)*. This option also adds the advantage of spring-loaded stabilizer wheels. |

FD1 Flexdraper® - Ground following like never before Featuring MacDon Flex-Float Technology , FD1 Series FlexDrapers continue to advance harvesting innovation. The flex advantage comes from a fixed reel to cutter bar relationship, which maintains a small gap between the reel fingers and cutter bar, while the Active Float System allows for instant lateral and vertical float response over rolling and uneven terrain. The result of our Flex-Float Technology

Close reel to cutterbar relationship

The MacDon FD1 FlexDraper features a fixed reel to cutterbar relationship. A small gap between the reel fingers and the cutterbar is maintained at all times, even at extreme flex, ensuring smooth, consistent, heads-first feeding of the crop over the entire width of the FlexDraper.

Active Float System

MacDon's Active Float System reacts instantly to changing ground conditions. This immediate float response means you can cut extremely close to the ground without pushing soil. Two sets of coil springs on the FM100 Float Module support up to 97% of the header weight. The instant float response provides 4.8 degrees of lateral float and 178 mm (7”) of vertical float, independent of the combine feeder house. Best of all, this is a simple reliable mechanical system requiring only one sensor, so things won't break down when your harvest is on the line. MacDon’s Active Float System keeps our headers true-to-the-ground for a clean, even cut every time.

Reel Performance

Unlike other headers, the movement of our heavy-duty reel picks up and gently places crop onto the drapers. The FD1 reel features 4" finger spacing and a uniquely shaped cam, which allows the fingers to get underneath lodged and low-podding crop to pick it up before it's cut. Along with the header tilt control, which hydraulically angles the knife from the cab and fore-aft reel positioning, our headers can be adjusted for the toughest harvesting challenges.

True Ground Following

The MacDon FD1 FlexDraper is a floating, three-section flexible header with a split reel. This allows the entire header frame, cutterbar, and reel to follow ground contours as a unit, flexing up to 254 mm (10") on either end, while maintaining a close reel to cutterbar relationship. This unique three-section design lets the FD1 FlexDraper deliver smooth, consistent, head-first feeding to the combine, even at extreme flex. |

| Size* | 25' (7.6 m) | 30' (9.1 m) | 35' (10.7 m) | 40' (12.2 m) | 45' (13.7 m) |

|---|---|---|---|---|---|

| Weight** Single Knife Drive with FM100 | 6240 lb (2830 kg) | 7210 lb (3270 kg) | 7695 lb (3490 kg) | - | - |

| Weight** Double Knife Drive with FM100 | - | - | - | 8170 lb (3706 kg) | 8460 lb (3837 kg) |

| Knife: Type / Drive / Speed |

Single or double knife (depending on size and application) / Hydraulic, MacDon design enclosed oil bath Wobble Box(es) / Single knife combine 1050 to 1400 spm, double knife combine 1100 to 1700 spm (speed varies depending on header size, faster knife speed on smaller headers or double knife headers) | ||||

| Guard Types Available |

Pointed DHT (double heat-treated), stub SM (sheet metal hold-down, forged bottom guard), stub F (forged top and bottom) | ||||

| Reel: Type / Drive / Speed / Fingers |

Pick-up reel, five or six bat, two-piece (double) or single, flip-over design, cam-leading finger control / Hydraulic / Combine 0 to 67 rpm (varies depending on combine model) / HD plastic, 152 mm (6") spacing, 279 mm (11") length | ||||

| Conveyor: Type / Drive / Speed / Delivery |

1057 mm (41.6") wide 680.4 g (24 oz) rubber skim-coated drapers, reversible double V-guide with tracking, integral seal on leading edge / Combine 0 to 194 m/min (0 to 636 ft/min) / Mechanical deck shift, opening width 1539 mm (60.6") to 1948 mm (76.7") | ||||

| Field-Installed Options |

Upper cross auger, stabilizer wheels, in-cab side draper speed control, slow speed transport, lateral tilt automatic header height control | ||||

*Product size availability varies by market

**All listed weights are approximations and will vary depending on header configuration. Check with your dealer for combine ratings. Weight includes FM100 Combine Adapter. The FM100 Combine Adapter weighs approximately 2400 lb (1089 kg); this number varies by combine model.

| Size | 25' (7.6 m) | 30' (9.1 m) | 35' (10.7 m) | 40' (12.2 m) | 45' (13.7 m) |

|---|---|---|---|---|---|

| Weight* Single Knife Drive with FM100 | 6760 lb (3067 kg) | 7460 lb (3384 kg) | 7760 lb (3520 kg) | 8230 lb (3733 kg) | - |

| Weight* Double Knife Drive with FM100 | - | - | - | 8370 lb (3797 kg) | 8800 lb (3992 kg) |

| Knife: Type / Drive / Speed / Guards |

Single or double knife / Hydraulic, MacDon design enclosed oil bath wobble box(es) / 1050 to 1400 spm, varies depending on header size / Pointed DHT (double heat-treated), strong, mud resistant profile | ||||

| Reel: Type / Drive / Speed / Fingers |

Pick-up reel, 2-piece (double) (FD125 1-piece), flip-over design, cam-leading finger control / Hydraulic / 0 to 67 rpm, varies depending on combine model / 279 mm (11") length, wear-resistant HD plastic, 102 mm (4") spacing (FD125, 152 mm (6") spacing) | ||||

| Conveyor: Type / Drive / Speed |

1057 mm (41.6") width, reversible 680.4 g (24 oz) rubber skim-coated drapers, double V-guide with tracking, integral seal on leading edge / Hydraulic / 0 to 194 m/min (0 to 636 ft/min) (Depending on combine model) | ||||

| Standard Features |

Adapters for most current model combines, hydraulic fore-aft reel positioner, hydraulic header tilt, cutterbar poly wear plates, auto-header height with header angle and ground pressure indicators | ||||

| Field-Installed Options |

Upper cross auger, stabilizer wheels, in-cab side draper speed control, slow speed transport, lateral tilt automatic header height control | ||||

*All listed weights are approximations and will vary depending on header configuration. Check with your dealer for combine ratings. Weight includes FM100 Combine Adapter. The FM100 Combine Adapter weighs approximately 2400 lb (1089 kg); this number varies by combine model.

| Center Draper | Feed Auger | |

|---|---|---|

| Size | 2000 mm (78.7") width | 1660 mm (65.3") width |

| Weight |

Approximately 2400 lb (1089 kg), varies by combine model | |

| Type |

Self-tracking, rubber-coated polyester fabric feed draper with rubber slats, hydraulic drive (reversible) |

Floating auger, mechanical drive (reversible), removable retracting fingers with full-retraction when reversing |

| Speed |

107-122 m/min (350 to 400 ft/min) |

185-206 rpm, varies with combine model |

| Header Flotation: Type / Vertical Range / Lateral Range (tilt) |

Two pairs of coil springs, independent adjustment, transport lock-out / 178 mm (7") / 4.8 degrees | |

Fits most current model combines.

Optimized Feeding for Serious Capacity

Optimized Feeding for Serious Capacity High Capacity Hydraulics

High Capacity Hydraulics